|

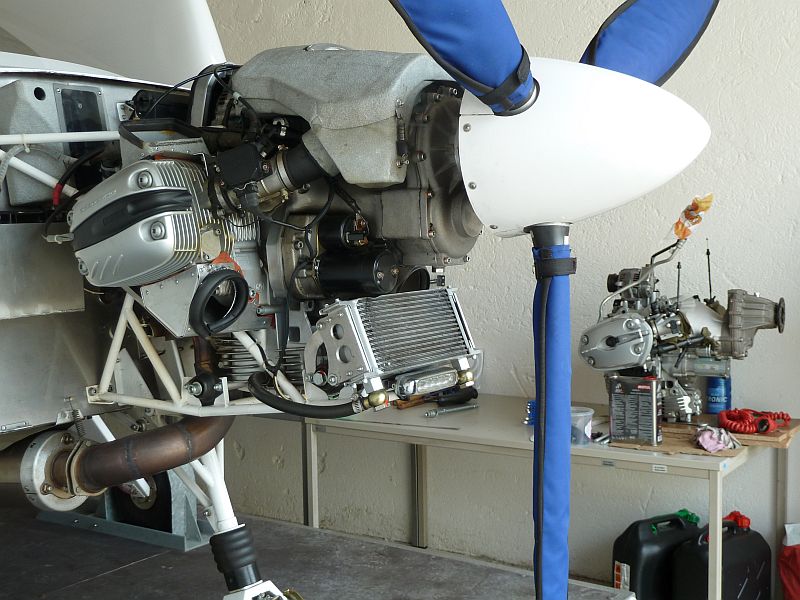

My choice is the BMW motorcycle engine!

This large-scale production engine, build 250 times “per day” is hard to beat in terms of reliability

and neither in the value for money.

First I enjoyed operating the BMW R 1100 S engine for about 200 hours.

(Link: Information regarding the R1100S installation).

But I could not resist installing the new BMW R 1200 GS engine (background).

All major advantages of the BMW engine are obvious:

- No carburetor-icing (Electronic fuel injection)

- No mixture-regulation

- Premium Unleaded (95 ROZ)

- Extremely low fuel consumption

- Very high power-/weight-ratio

- 3 - way catalytic converter (closed loop) can be used

- Significantly less expensive than a certified engine

...

The engine is equipped with a special balancing-shaft to eliminate vibrations. Additionally the automatic centrifugal clutch

of the gear (the propeller starts turning @ 2700 min-1 ) eliminates harmful low rpm vibration to the plane at all.

The new R 1200 GS engine with the Takeoff gear is 10 kg less than my old R1100S-installation at 18,5 % more torque

(115Nm @ 5500 1/min).

BMW uses a CAN bus system not really usable in a plan. The Bosch Motronik of the R 1100 S engine falls back to a standard mode if for example a sensor signal is missing; while the bus system might just shut the engine down to avoid possible trouble.

Takeoff offers a fitted harness for the new BMW-engine (Plug & Play) and a programmable engine control unit from Trijekt.

Just remove and replace does not do it – Engine mount, harness, engine control unit, ... need to be replaced.

The engine mount is a little more compact now. I gave up the idea to mount the new muffler (white template) behind the engine – the heat needs to be transferred out of the engine compartment somehow…

... the muffler will be underneath the engine...

The shape of the cowling has slightly changed...

I am using two 90° copper-elbows (hardware store, roofing) to channel the cooling air to the lower cylinder surface.

I would like to address a serious appeal to all interested fellows because of the feedback I am receiving frequently:

You will not have fun with your engine (BMW is no exception) if you fail to cool the engine sufficiently!

The fact, that there is no cooling duct for the cylinders on a BMW motorcycle, should not mislead you to cut a few holes

into the cowling, hoping for the cool air to find the “hot spots” automatically. This is not going to work!!! As there are

cooling ducts for the cylinders of a Rotax engine, you need to apply such ducts (because of the small cooling-fins in

sufficient dimension) to the BMW engine as well.

It looks a little more stylish than before, despite the “lowered“ muffler…

Still under construction ... R/H view

Still under construction ... L/H view

...

Cowling painted

I took the Cherry (on trailer) to EDRN for extensive test flights during my vacation (August).

Finally, I went flying when the desperately awaited flight-clearance arrived! Following extensive engine-

runs on ground I did not face any mentionable surprise… The R 1200 GS engine runs significantly smoother

than the 1100 engine due to the additional balancing-shaft. Installing the smaller (BMW) oil-cooler again

turned out to be correct, since oil-temperature (@ 127 kts GS) is still low at 80°C.

An efficient air-cooling of the cylinders is obviously essential.

The MGL E-3 (middle up) monitoring EGT and CHT is new.

Obtain a Cherry-Builder-File with a License at www.bx-2.de

|